In today's competitive production environments, achieving near-perfect quality while minimizing waste is a critical challenge. This is where high-precision color sorter machines come into play, revolutionizing how industries separate materials based on optical characteristics.

What is an Optical Color Sorter?

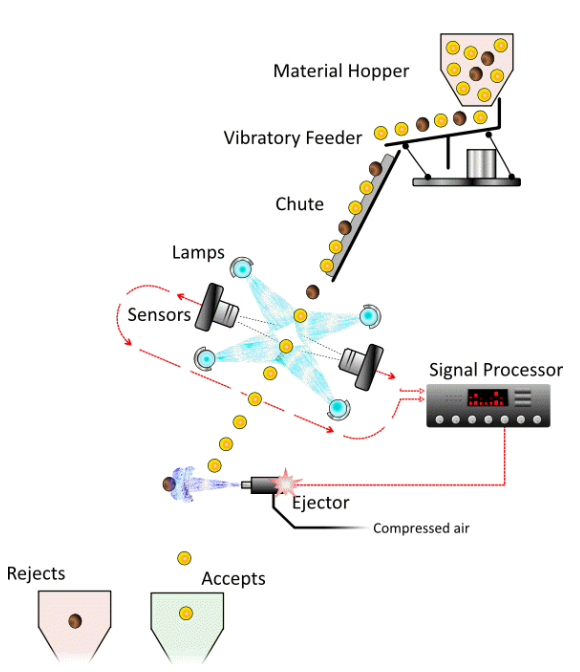

At its core, a color sorter is an intelligent vision system that acts like a superhuman inspector. It scans thousands of individual items—such as grains, seeds, or recycled materials—every second. Using advanced sensors and lighting, it captures detailed color and shape data of each particle as they flow rapidly through the machine. When it detects an unwanted item (like a discolored grain, a stone, or a different type of plastic), it commands a precise air ejector to remove the impurity from the stream, ensuring only the desired material continues down the production line.

The Heart of Modern Sorting: AI and Deep Learning

The leap from traditional sorting to high-precision sorting is driven by AI Deep Learning. Unlike older systems that relied on simple color thresholds, modern algorithms are trained on vast image libraries. They learn to identify not just obvious defects but also subtle variations in color, shape, texture, and even biological flaws that are invisible to the naked eye. This “learning” capability allows the system to adapt to new materials and increasingly complex defects, continuously improving its accuracy towards that 99.9% purity goal.

Why is 99.9% Purity a Game-Changer?

A purity rate of 99.9% translates to just one defective item in a thousand. In sectors like food processing (e.g., for Rice and Beans) or high-value material recovery (e.g., Plastic Flakes, Glass, and Minerals), this level of precision is transformative. It means:

Maximized Yield: More good product is correctly kept, directly boosting profitability.

Minimized Waste: Impurities are removed early, saving costs on downstream processing and waste disposal.

Uncompromised Safety & Quality: Ensures final product consistency and safety, protecting brand reputation.

Engineered for Efficiency: Speed and Accuracy in Harmony

High precision cannot come at the cost of speed. Leading optical sorting technology combines ultra-high-resolution cameras and powerful processing units to make millions of decisions per hour. The key to maintaining this speed without loss of good material is Ultra-Low Carryover. This is achieved through high-frequency, smart ejectors that fire with pinpoint accuracy for microseconds, ensuring only the targeted defect is removed while valuable material stays on course.

From farm to factory, AI-driven optical sorting is setting a new standard for purity and efficiency. By integrating such intelligent systems into their production lines, businesses are not just automating a step—they are fundamentally upgrading their quality control and operational sustainability.

ISO 9001

Certified Quality Management System

CE Mark

European Union Compliance Certified

5000+

Successful Global Installations

An optical color sorter is a highly automated machine that acts as a robotic quality inspector for bulk materials. Its primary job is to separate good product from impurities or defective items using advanced vision technology. Think of it as a machine with superhuman eyesight and a lightning-fast brain, making millions of quality decisions every hour on a production line.

The core principle is based on scanning. As materials like grains, nuts, plastics, or minerals flow through the machine, they pass under powerful sensors. These sensors, which can include high-resolution cameras and specialized lights, capture the exact color, shape, and even the internal structure of every single particle. Sophisticated software then analyzes this data in real-time, instantly identifying items that don't meet the desired quality standards.

This technology is crucial for achieving 99.9% purity. In practical terms, it means removing tiny black stones from white rice, discolored beans, different types of plastic in recycling streams, or defective seeds. By ensuring only the best product moves forward, optical color sorters are fundamental to maximizing yield, ensuring food safety, and minimizing waste in industries from agriculture to recycling.

The 4-Step Precision

Sorting Process

The remarkable accuracy of a modern color sorter is the result of a seamless, high-speed process. Each step is engineered for precision, working together to achieve the industry-leading purity rates that define AI-driven optical sorting.

1. Material Feeding & Distribution

Consistency is key from the very start. Raw material is fed from a hopper and carefully spread into a single, even layer. This is typically done using high-speed vibrators or chutes. The goal is to ensure every grain, bean, or flake is perfectly aligned and separated as it falls. This prevents particles from overlapping or clumping, guaranteeing each one is fully visible for inspection in the next critical step.

2. High-Speed Image Detection

This is the "seeing" phase. As the monolayer of material passes through the inspection area, it is scanned by an array of high-resolution cameras. These cameras, often coupled with different light sources (like visible light, infrared, or ultraviolet), capture thousands of detailed images per second. This multi-spectral imaging allows the system to detect defects that are invisible to the human eye, such as slight color variations, subtle biological damage, or differences in material composition.

3. Intelligent Image Processing (The AI Brain)

Here, captured images become decisions. The visual data is sent to a powerful processor running advanced software. By comparing the attributes (color, shape, size) of each particle against pre-programmed acceptance criteria, the system classifies items as "good" or "bad" in milliseconds. Modern systems using AI deep learning can recognize complex patterns and learn to identify new types of defects, continuously improving their accuracy and adaptability.

4. Precise Rejection (Ejection System)

The final step is physical separation. When a defect is identified, the processor calculates its exact location and triggers an ultra-fast response. At the perfect moment, a bank of precisely aimed air nozzles releases a tiny, focused burst of compressed air. This puff of air knocks only the defective item out of the product stream and into a reject channel, while the good material continues undisturbed. This technology enables the ultra-low carryover that minimizes the loss of valuable product.

Industry-Specific Sorting Solutions

Our high-precision optical sorting technology is not a one-size-fits-all tool; it is a versatile platform engineered to meet the distinct challenges of diverse sectors. We provide tailored solutions that deliver the 99.9% purity standard, whether the goal is ensuring consumer food safety or achieving high-value material recovery in industrial settings.

1. Agricultural & Food Processing

In the food industry, purity is synonymous with safety and quality. Our sorters act as an ultimate quality gateway, enhancing food safety and protecting brand reputation by meticulously removing physical contaminants and substandard product. The technology excels in handling delicate foodstuffs at high speeds without damage.

Applications include precise sorting for Grains & Cereals like rice—where it removes chalky, yellow, or broken grains—as well as wheat and corn. For Seeds & Beans such as soybeans, coffee, and cocoa, it provides superior defect detection. In Nuts & Kernels, it ensures high-speed removal of shells, shriveled kernels, and aflatoxin-infected peanuts and cashews. Even for Specialty Crops like tea leaves and dehydrated vegetables, optimized sensors perform accurate grading by color and shape.

2. Plastic & Industrial Recycling

Our sorters are pivotal in powering the circular economy, transforming waste streams into high-purity, valuable feedstock. By accurately separating materials by color and polymer type, we enable higher-quality recycling and better end-market value.

Key capabilities include sorting PET Flakes to achieve bottle-to-bottle grade purity by separating clear from colored flakes and removing contaminants like PVC. For HDPE, PP, and ABS rigid plastics, the machines efficiently sort by both color and polymer type. The technology also extends to E-Waste & Glass recycling, where it efficiently separates crushed glass (cullet) by color and removes non-glass impurities from electronic scrap.

3. Mining & Mineral Sorting

In mining, our technology introduces a smart, dry processing method that significantly boosts efficiency. It reduces energy, water, and chemical usage by reducing processing costs through pre-concentration of ores, allowing valuable material to be upgraded early in the process.

This is applied in sorting Industrial Minerals like quartz, talc, and salt to remove impurities. For valuable Ores such as gold, copper, and lithium-bearing minerals, high-capacity sorting provides a method to pre-concentrate material, dramatically reducing the volume sent to energy-intensive downstream processing.

Why Choose Our Optical Sorting Technology?

In today's competitive landscape, where efficiency and quality are paramount, settling for basic sorting is a disadvantage. Our technology represents the forefront of industrial automation, integrating cutting-edge artificial intelligence with advanced optoelectronics to deliver a solution that is not just effective today but is engineered for the future demands of your production line.

1. AI Deep Learning Algorithms

Moving beyond the limitations of simple color filters, our systems are powered by a true AI Deep Learning engine. This technology learns and adapts like a human expert, but with unparalleled speed and consistency. It analyzes complex visual patterns, enabling it to make sophisticated distinctions—such as telling the difference between a harmless natural variation and a critical safety defect like mold. The system continuously improves its performance by learning from the material it processes, adapting to new types of defects without needing constant manual adjustment. Furthermore, it can sort based on multidimensional criteria including precise shape and texture recognition, allowing for the exact grading of premium products.

2. Multispectral & Hyperspectral Imaging

Our machines possess a form of "supervision" by utilizing light spectra invisible to the human eye. This capability is key to solving some of the toughest sorting challenges. With InGaAs Infrared (NIR) Technology, the system can differentiate materials based on their internal composition—like identifying a clear plastic fragment in white rice or a stone in coffee beans—by detecting differences in density and molecular structure. UV Fluorescence imaging is another powerful tool, capable of pinpointing specific contaminants like toxic aflatoxin in nuts or identifying different polymer types in complex recycling streams, ensuring purity at a fundamental level.

3. High-Frequency Smart Ejectors

The precision of the digital brain must be matched by the physical action of rejection. Our ejection system is engineered for extreme performance and reliability. Featuring ultra-fast magnetic levitation solenoid valves with a response time of less than 1 millisecond, it ensures defective items are struck with pinpoint timing. Built for endurance, these components are rated for over 10 billion cycles, supporting relentless 24/7 operation. The system is also intelligent, adjusting air pressure dynamically based on the size and type of defect, which optimizes compressed air use and can reduce related energy costs by up to 20%.

4. Cloud Connectivity & Remote Diagnostics

Our technology keeps you connected and in control. Through integrated cloud connectivity, you can monitor key performance indicators—like real-time yield, purity rates, and machine health—from anywhere via a smartphone or computer dashboard. This connectivity enables powerful remote diagnostics and support. Our engineering team can securely access the system to perform software updates, diagnose issues, and often resolve them remotely. This minimizes unplanned downtime and reduces the need and cost for on-site service visits, ensuring your operation runs smoothly and efficiently.

Choose the Right Model for Your Production Scale

Our color sorting machines come in various configurations, from compact units for small-scale specialty processing to high-capacity industrial lines. Explore our core series below to find the perfect balance of throughput and precision.

This section features real working videos of various color sorter machines, covering sorting scenarios for more than ten types of materials including ores, grain and oil, fruits and vegetables, plastics, and sand and gravel. It intuitively demonstrates the sorting principles, working processes and practical application effects of different color sorters, offering a comprehensive understanding of their precise sorting capabilities and application scope.

Color Sorter Machines Video

This section features real working videos of various color sorter machines, covering sorting scenarios for more than ten types of materials including ores, grain and oil, fruits and vegetables, plastics, and sand and gravel. It intuitively demonstrates the sorting principles, working processes and practical application effects of different color sorters, offering a comprehensive understanding of their precise sorting capabilities and application scope.

Comparative Performance Data

| SPECIFICATION | Power | Capacity | Camera Number | Accuracy | Size (mm) | Weight |

|---|---|---|---|---|---|---|

| M1 | 1 KW | 0.5-1.5 T/H | TWO | 99.99% | 950X1550X1600 | 350kg |

| M2 | 1.2 KW | 1-3 T/H | FOUR | 99.99% | 1250X1550X1600 | 450kg |

| M3 | 2.6 KW | 2-5 T/H | SIX | 99.99% | 1800X1650X2020 | 750kg |

| M4 | 2.8 KW | 3-6 T/H | EIGHT | 99.99% | 2170X1650X2020 | 900kg |

| M5 | 3.2 KW | 4-7 T/H | TEN | 99.99% | 2500X1650X2020 | 1050kg |

| M6 | 3.6 KW | 5-8 T/H | TWELVE | 99.99% | 2850X1650X2020 | 1250kg |

| M7 | 4.1 KW | 6-10 T/H | FOURTEEN | 99.99% | 3150X1650X2180 | 1400kg |

| M8 | 4.5 KW | 7-12 T/H | SIXTEEN | 99.99% | 3460X1650X2180 | 1600kg |

| M10 | 5.5 KW | 7-20 T/H | TWENTY | 99.99% | 4100X1650X2180 | 2000kg |

| M12 | 6 KW | 10-20 T/H | Twenty Four | 99.99% | 5000X2000X2300 | 2900Kg |

| B300 | 2 KW | 1-3 T/H | TWO | 99.99% | 2750X980X1530 | 700kg |

| B600 | 2.5 KW | 2-5 T/H | FOUR | 99.99% | 2750X1280X1530 | 800kg |

| B1200 | 4.8 KW | 3-8 T/H | EIGHT | 99.99% | 2750X1950X1580 | 1200kg |

| DB1200 | 5 KW | 3-10 T/H | SIXTEEN | 99.99% | 3400X2050X2500 | 1900kg |

Customization & Scalability

Our standard models cover a wide array of applications, but we understand that unique materials or processes may demand a tailored approach. We specialize in engineering bespoke sorting configurations to solve specific challenges.

Dual-Vision Systems: For comprehensive inspection, we integrate front and rear camera setups. This 360-degree scanning capability ensures no defect is hidden, providing absolute confidence for premium product grading or challenging materials.

Chute Geometry: The path the material takes is critical. We engineer custom-designed chutes and feeding systems optimized for specialized grain sizes, elongated products, or particularly fragile materials to ensure gentle handling and optimal presentation to the sensors.

Modular Expansion: Your business growth is integral to our design philosophy. Many of our mid-range models feature a modular architecture, allowing you to start with what you need and seamlessly upgrade by adding sorting chutes or enhanced processing units as your production demands increase.

Proven Results: How We Empower Businesses Worldwide

With over 5,000+ installations across 50+ countries, our color sorters are more than just machines—they are profit-driving assets. From family-owned farms to multinational recycling plants, we deliver purity you can trust.

Case Study 1: Scaling Rice Production in Southeast Asia

The Challenge: A major rice miller in Thailand struggled with a high percentage of "chalky" and "yellow" grains, leading to lower market prices and high manual sorting costs.

The Solution: Installation of three Standard-X4 series color sorters.

The Result:

99.9% Purity Achieved: Met premium export standards for the EU market.

30% Yield Increase: Reduced the "carryover" of good grains into the reject bin.

ROI: The equipment paid for itself within 8 months of operation.

Case Study 2: Closing the Loop in PET Recycling (Europe)

The Challenge: A recycling facility in Germany needed to separate blue and green PET flakes from clear ones to produce bottle-to-bottle food-grade resin.

The Solution: Integrated our Belt-Pro 800 with InGaAs Infrared technology.

The Result: Successfully removed non-visible PVC contaminants, achieving a purity level of 99.5%, allowing the client to sell their recycled flakes at a 25% premium.

What Our Clients Say

"The AI-driven interface is a game changer. We switched from a traditional CCD sorter to this deep-learning model, and the accuracy on broken cashews improved instantly. The remote support team helped us calibrate the machine in hours, not days."

"Reliability is our number one priority. We run our plastic recycling line 24/7, and the ejectors on these machines have been flawless for over two years. Highly recommended for industrial-scale sorting."

Global Certifications & Standards

We adhere to the strictest international quality and safety standards:

ISO 9001:2015 Quality Management System

CE Marking (European Conformity)

UL Certification (for North American markets)

FDA-Compliant materials for food-contact components

Ready to Elevate Your Product Purity?

Don't leave your product quality and profitability to chance. Whether your goal is to meet stringent international export standards, maximize yield, or reduce operational waste, our team of optical sorting experts is ready to partner with you. We provide tailored solutions to help you achieve the 99.9% purity that defines industry leadership.

Get a Free Sorting Performance Test

Choosing the right machine starts with understanding its potential on *your* material. We invite you to send us a sample for a complimentary laboratory sorting test. You will receive a detailed, objective report that includes:

Sorting Accuracy Results: Clear “Before vs. After” analysis with purity metrics.

Optimized Machine Configuration: A specific model and setup recommendation for your needs.

Estimated ROI & Throughput Analysis: A practical projection of performance and payback.

Comprehensive After-Sales Support

Our commitment begins when your machine is installed. We build long-term partnerships through unwavering support.

Global Installation: On-site setup and calibration by our certified engineers.

24/7 Remote Assistance: Instant troubleshooting via our secure, cloud-based diagnostic platform.

Training Programs: Comprehensive on-site operator training to ensure peak performance.

Original Spare Parts: Extensive global inventory of ejectors, sensors, and filters for fast shipping.