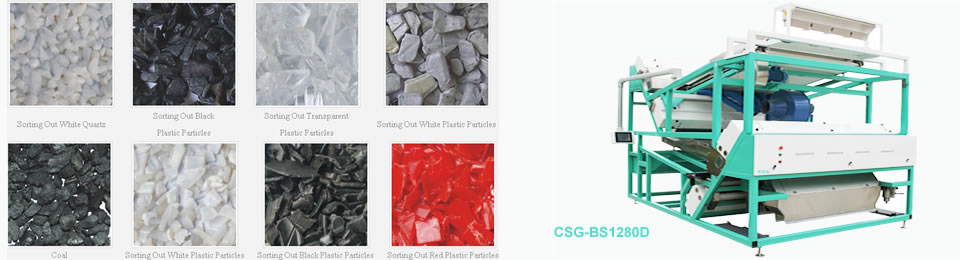

Industrial Color Sorter

Apply to separating different Coal, Quartz Sand, Monosodium Glutamate, Recycled Plastic, Halite, Monocrystalline Silicon, Glass, and Other Industrial Granules

1. Feeding System: Feeding system with innovative winnowing function, automatic winnowing for ethereal substances and dust on materials, which can effectively enhance the accuracy of color sorting. 2. Discharging system: The industry's only originated a bucket with a discharging system, finished product waste, according to the different needs of customers can be set flexibly realize the sorting can lower again to check, no need to replace the function of the hopper. 3. Operating System: One-key intelligent automatic operation, omitting multiple steps, quick response, easy to grasp; concise response to color sorting requirements of materials of different batches and different impurities. One-key intelligent system can automatically identify and adjust, no re-set is needed to ensure the best color sorting effects; truly interactive, intelligent docking, you can sit back and relax. 4. Processing System: Enhanced DSP+FPGA international cutting-edge processer technology, high processing efficiency, more accurate real-time processing capability; super computing power, massive data processing, which can meet the requirements for complex calculations of a variety of modes, it is a smart model in the industry; automatic alarm functions and prompts for non-normal color sorting requirements, as well as abnormal air supply; modular design, strong scalability, easy maintenance and upgrade. 5. Image Acquisition System: Dedicated 2048 high-speed line scan CCD image sensor for international cutting-edge industries, and special color sorting cameras tailored by top international suppliers, can precisely identify subtle spots of 0.04mm2。

COLOR SORTER GROUP

COLOR SORTER GROUP