What Is Color Sorter

Color Sorter also named optical sorting machine, it is according to the color differences of product, using high-resolution CCD optical sensor to drive solenoid valve to sort out different granular materials.

CSG provides a broad portfolio of sensor-based optical sorting technology.Automated sorting technology is faster and more efficient than its traditional counterpart.Promote sustainable development for Food Industry, Waste Recycling Industry, Mining Industry.

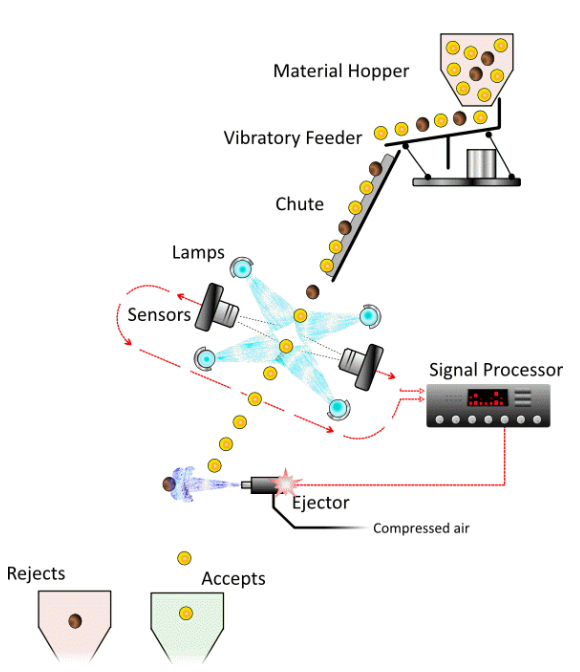

How the color sorter works

The selected material enters the machine from the hopper at the top. Through the vibration of the vibrator device, the selected material slides down the channel, accelerates its falling into the observation area in the separation room, and passes through the sensor and the background plate. Under the action of the light source, according to the light intensity and color change, the system generates an output signal to drive the solenoid valve to blow out the heterogeneous particles to the waste chamber of the receiving hopper, and the good selected material continues to fall into the finished product chamber of the receiving hopper, so as to achieve the purpose of separation

Development History of Color Sorter

In the 1930s, American companies and British companies first developed rice color sorting machines. Japan and South Korea succeeded in developing and commercializing them in the 1970s and 1980s. It was not until the 1980s that China introduced color sorters. Although China's color sorter industry started relatively late, as a large agricultural country, China's color sorters have occupied more than half of the global market. CSG color sorter enjoys a good reputation worldwide

Color Sorter Working Principle

Color Sorter working principle is to use the photoelectric detection technology and image acquisition system to obtain the (RGB) red, green and blue optical information of the material, convert the optical characteristics of the material into a photoelectric signal, and then send the signal to the control system to drive the ejector uses compressed air to blow out foreign particles in the material.

CSG Color Sorter use world top SENSOR-BASED OPTICAL SORTING TECHNOLOGY, sorting range from 0.01mm to 5 cm, sorting precision more than 99.9%. Solve the high dust, high output, complex colors, etc sorting problems under harsh environment.

Working System

The color sorter is mainly composed of a feeding system, an optical detection system, a signal processing system and a separation execution system.

Sorting Steps

1. The material enters the machine from the collecting hopper on the top, and the selected material falls along the feeding distribution trough through the vibration of the feeding device (vibrator).

2. The material passes through the vibrator at the upper end of the chute and accelerates down the chute into the sorting box

3. After entering the sorting box, it passes between the image processing sensor CCD and the background device. Under the action of the light source, the CCD receives the synthetic light signal from the selected material, so that the system generates an output signal, which is amplified and transmitted to the FPGA +ARM arithmetic processing system, and then the control system sends instructions to drive the injection solenoid valve to move, blowing the heterochromatic particles into the waste cavity of the discharge hopper to flow away.

4. The good selected materials continue to fall into the finished product cavity of the receiving hopper and flow out, so that the selected materials can achieve the purpose of selection.

Components Of The Color Sorter

1. Feeding part: It is composed of feeding hopper, feeding port, vibrator, etc. The feeding device is connected to the frame by an anti-vibration spring. The selected material slides down into the channel through the feeding hopper, the inlet and the vibrator.

2. Channel: It is composed of inclined and fixed aluminum alloy slides, from which the selected materials enter the sorting chamber evenly.

3. Sorting device: It is composed of two sorting boxes at the front and back, with camera, light source, reflector and other components inside. The signals of each channel are collected and processed from here and transmitted to the main control machine.

4. Electrical box: Most electrical components are installed in the sealed box behind the machine, which is an important part of the machine. It is responsible for controlling the work of the electrical part and controlling the spray valve to complete the color selection process of removing impurities.

5. Blowing device: It is controlled by the main control board, the spray valve board, the valve line and the spray valve, used to remove unqualified materials.

6. Receiving hopper: It is composed of receiving chamber and receiving pipe. The receiving pipe receives qualified products and the receiving room receives unqualified products.

7. Frame structure: composed of brackets.

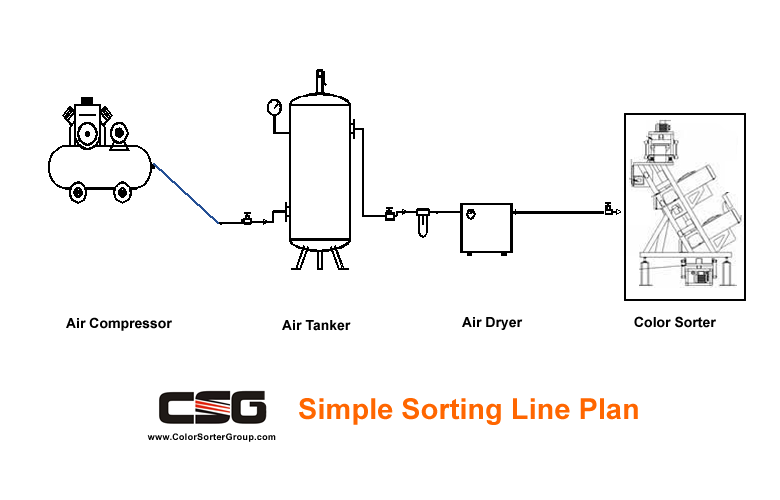

8. Air supply system: It is composed of filtration, decompression, and air pressure display as one part, and provides qualified compressed air to the whole machine. When the air pressure is lower than a certain value, it will automatically alarm and stop working.

9. Heating device: It is composed of a heating film behind the slide, and is controlled by an air switch and a temperature control switch in the electrical box to make the channel work at an appropriate temperature.

CCD & CAMERA

RGB full color tri-chromatic CCD image acquisition system, High resolution camera with 5340 pixel identifying tiny defects up to 0.01mm2.

IMAGE PROCESSING

Strong industry-grade digitization processor, image acquisition and processing in high speed, consistency of signal path and signal reliability is secured.

SORTING ALGORITHM

Excellent combination of mechanical structure and tri-chromatic control system, guarantee 99.999% accuracy and amazing 50:1 rejection rate.

Type of Color Sorter

Color Sorter type have Chute type, Multilayer type and Belt type

Choose the right type according to different application scenarios.

Chute Type Color Sorter

Chute Type machine apply to sorting: Rice, Wheat, Corn, Maize, Millet, Sorghum, Quinoa, Buckwheat, Oats, Barley, Cardamon, Sesame Seeds, Groundnut, Peanut, Soybean, Coffee Bean, Pea, Mung Bean, Lentil, Vicia Faba, Fava Bean etc.

Multilayer Type Color Sorter

Multilayer type machine apply to sorting: Tea, Dehydrated Vegetables, Herb, Dried Flower, Leaf Products etc

Belt Type Color Sorter

Belt type machine apply to sorting: Nuts, Cashew, Almond, Pistachio, Sunflower Seeds, Watermelon Seed, Raisin, Lycium Chinense, Jujube, Cotton Seed, Chili, Shrimp Skin, Ore, Coal, Salt, Sugar, Glass, Plastc, Pearl, Pill, Gum, Industrial products etc.

Channels Model of Color Sorter

The color sorter divides the slideway into a section every 10mm, and the nozzle is also installed every 10mm, called the channel, 1 chute is equal to 64 channels

- 64 channels

- 128 channels

- 192 channels

- 256 channels

- 320 channels

- 384 channels

- 512 channels

- 640 channels

- 768 channels

Application Field Of Color Sorter

CSG Color Sorter has been widely used in many industry in the world. Such as agricultural products, food and mining industries, The most common use is sorting rice, wheat, corn, peanut, a variety of beans, seeds, tea, herbs, dried vegetables, recycled plastic, salt and ore etc

Agricultural Products Sorting

The color sorting machine is mainly used for the classification of grains (agricultural products). The rice sorting industry is the first big market. The rice sorting technology uses high-resolution CCD optical sensors to separate stones, black rice, etc., based on the color difference of the rice (hulled rice) material. This is the last step after polishing the rice with the rice polishing machine. The second sorting market is used for wheat, corn, peanuts, various beans, sesame and other coarse grains. Sorting machine can improve product quality and increase social benefits

Food Sorting

Color sorters are used in the food processing industry, such as coffee, nuts and oil crops, and shelled items (such as sunflower seeds). Compared with manual sorting, the machine saves labor and time, is more efficient, and has lower processing costs.

Ore Sorting

In the ore classification industry, it is also called sensor-based classification technology. The optical color sorter (CCD color camera) combines X-ray sorting technology and NIR Sorting(Near Infrared Spectroscopy) to select impurities in ore, mineral, stone and sand products, or divide ore into two or more categories.

Waste Sorting and Recycling

In the recycling industry, the color sorter can distinguish between colored and colorless PET and colored and colorless HDPE flakes, and can separate flakes by color before repelletizing. Plastic color separators are used to separate mixed color plastic flakes or particles. Plastic type separators (sensor-based sorting technology) are used to separate plastics of the same color but different materials. The industry-recognized technology is to use a chute color sorter to classify plastic particles, and a belt-type color sorter to classify plastic sheet products.

Common color sorter product name

Common color sorter is named with the sorted item, such as rice sorting industry, it is called rice color sorter

- Rice Color Sorter

- Grain Color Sorter

- Nuts Color Sorter

- Bean Color Sorter

- Tea Color Sorter

- Salt Color Sorter

- Ore Color Sorter

| Sorting Accuracy | Voltage | Light Source | Camera Pixel | Image Sensor |

| 99.9% | 220V/380V | LED | 5400 Pixels | CCD |